Installing and Maintaining PVC and WPC Products

Installing and Maintaining PVC and WPC Products

Have you ever found yourself staring at beautifully designed spaces and interiors, wondering about the flawless finish and beauty? The secret may just lie in the creative use of PVC foam boards and WPC products.

Following the right procedures is important to guarantee the longevity and optimal performance of PVC foam boards during installation and maintenance. With an emphasis on Kerala PVC foam board manufacturers and Kerala PVC board prices, these guidelines will assist you with the installation and maintenance.

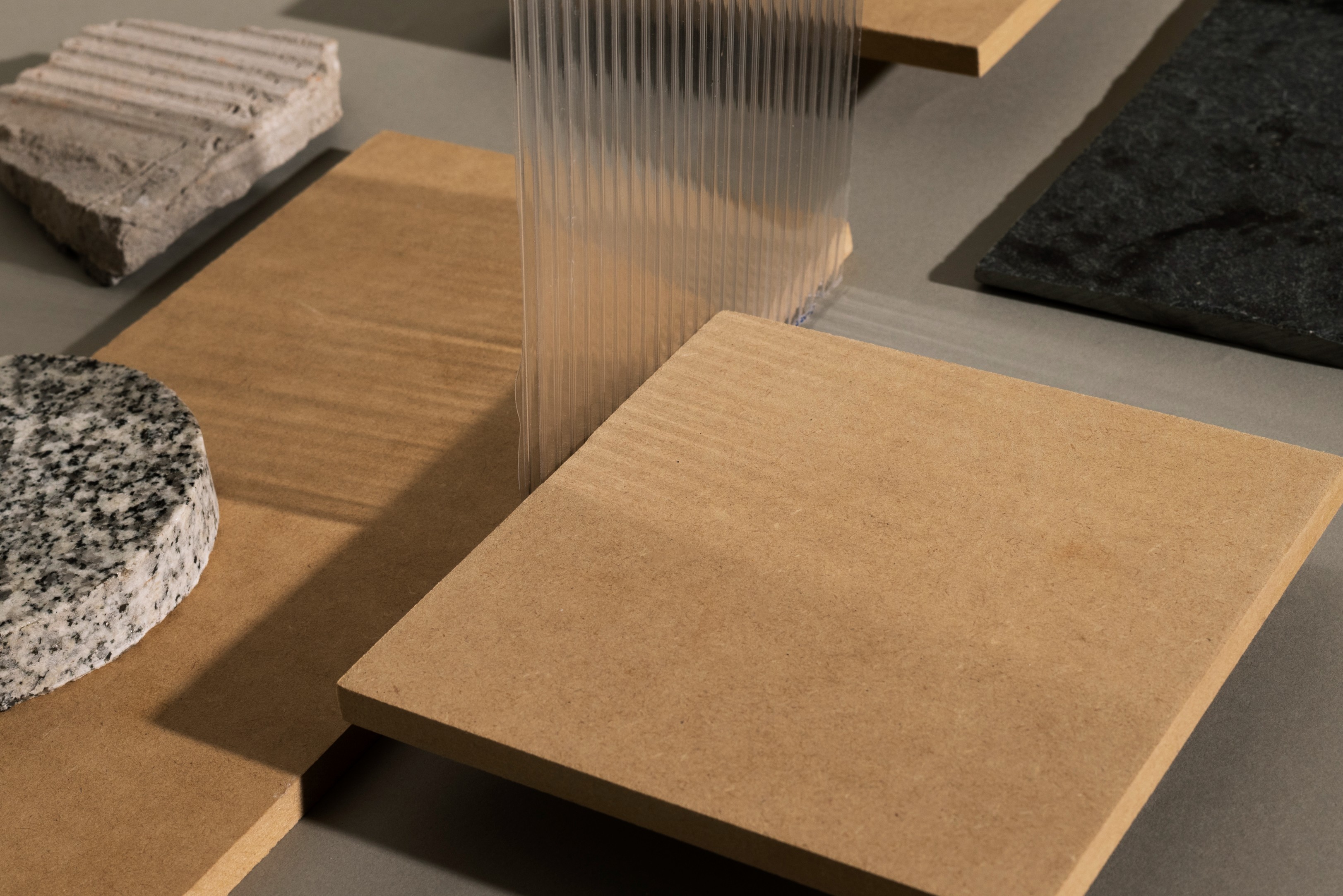

What are PVC and WPC Boards?

Solid wood panels are becoming more costly day by day. PVC (polyvinyl chloride) foams are a cost-effective alternative to solid wood panels.

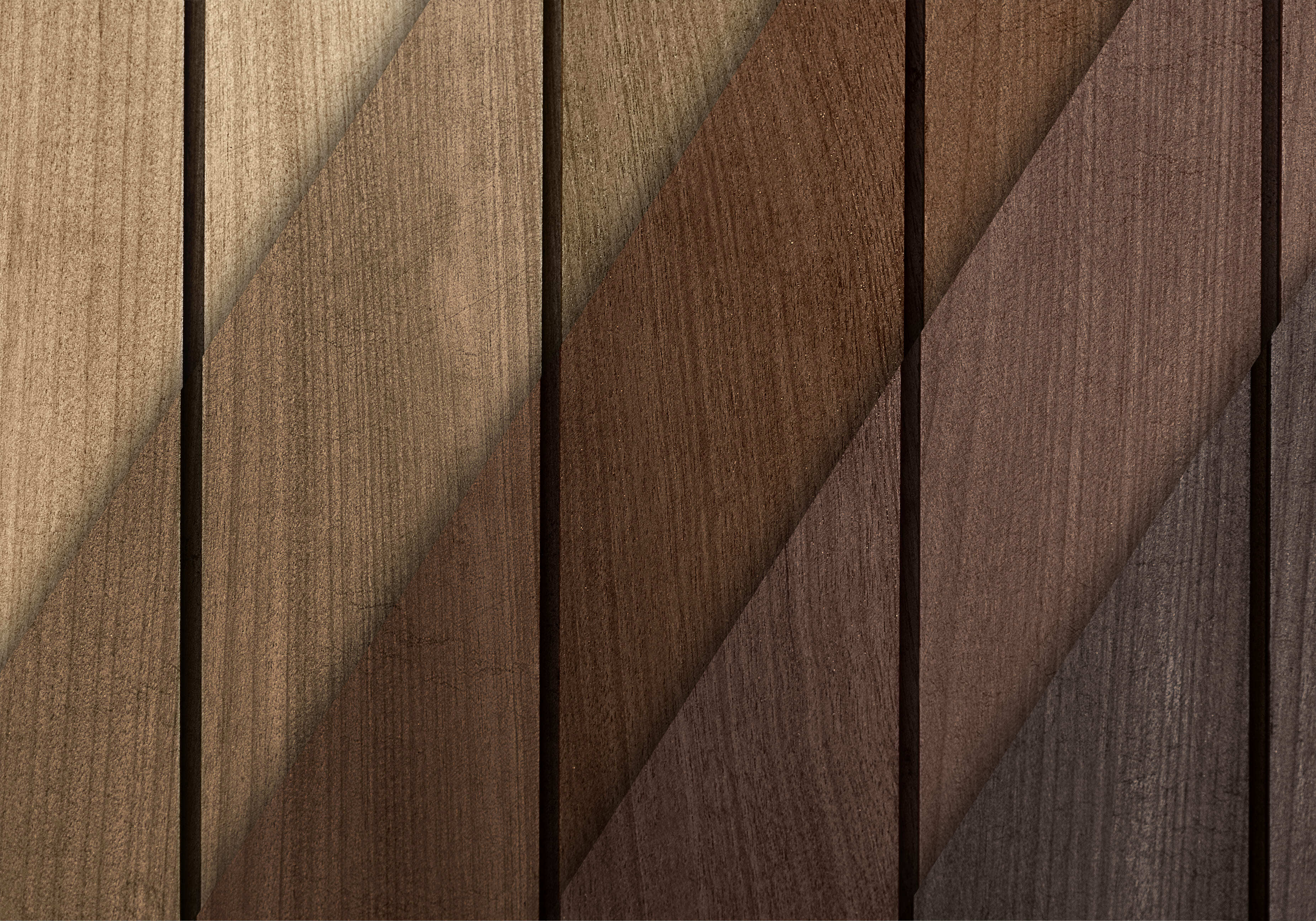

A combination of wood fibers, thermoplastics, and other materials are used to create WPC boards in Kerala.

Benefits of PVC foam boards include:

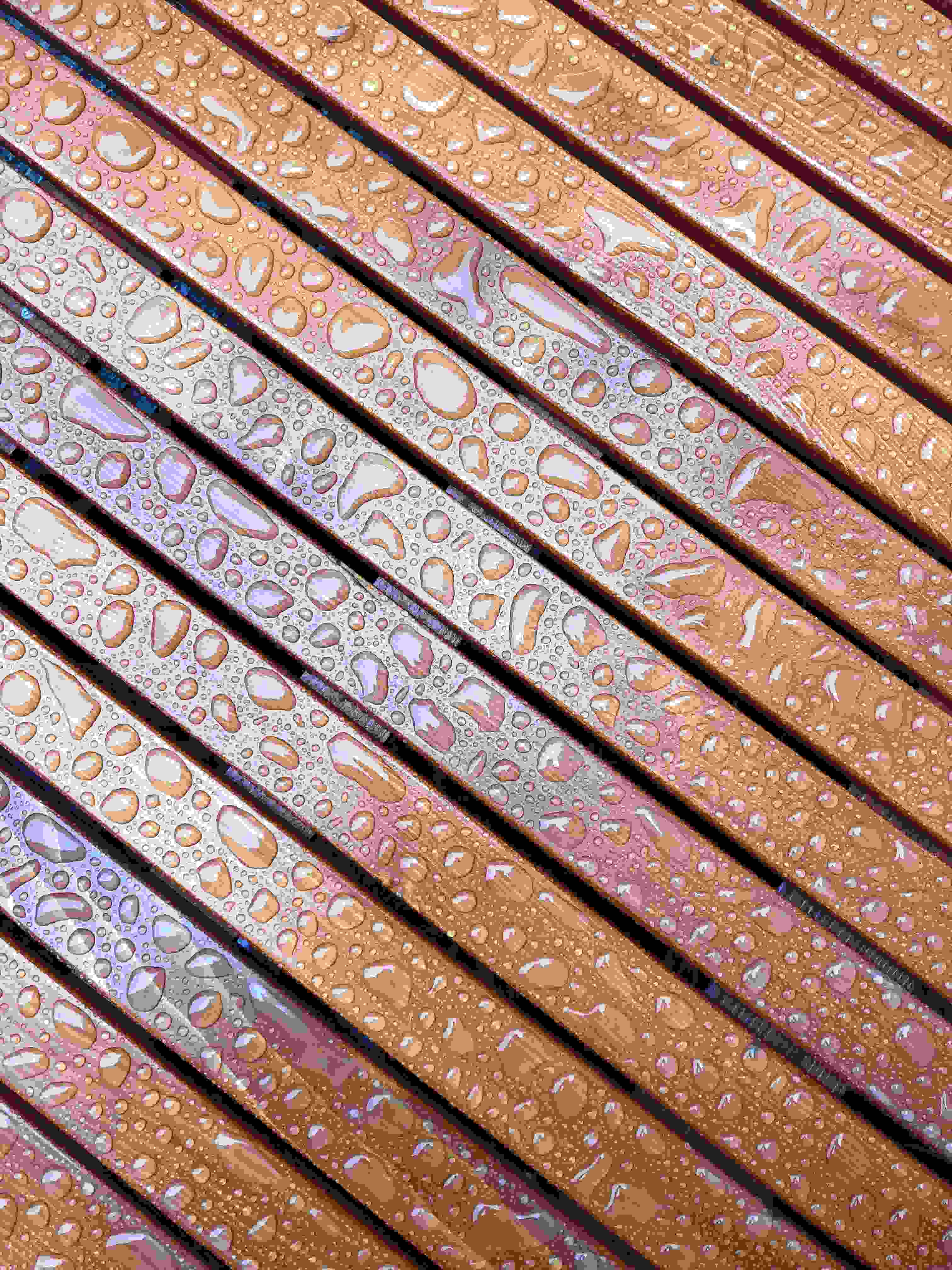

Durability: PVC foam boards are popular for their exceptional durability. PVC sustains many years without breaking down due to rot, moisture, or even hard impacts.

Lightweight: PVC foam boards are significantly lighter when compared to solid wood panels. It can be handled effortlessly and installed easily.

Low Maintenance: Compared to wood, PVC requires less regular washing and less repair over time.

Thermal Insulation: PVC foam boards are good for thermal insulation. They resist heat and severe weather conditions.

How to Install PVC and WPC Products

- Surface Preparation:Before Installing PVC and WPC boards, ensure that the surface is free of dust or any signs of moisture; moreover, you should prepare it precisely as required. Dust or grease on the surface should be eliminated.

- Measurement and cutting: Cut and measure the foam according to your requirements. Use the necessary, safe tools for cutting. Make sure that you wear safety equipment with goggles.

- Mounting and sealing: After that, the panels must be very consciously installed onto the surface. Mount the panels using appropriate screws, nails and adhesives. With adhesives, PVC panels can be installed for a more streamlined look.

- Expansion Gaps: It is necessary to consider the expansion gaps while shipping PVC foam boards. Temperature variations cause these boards to swell and shrink.

Maintenance

PVC forms require very little maintenance, but if you are looking for even more longevity and durability, you can follow several steps for maintenance.

Limit heat exposure: Denwud PVC foams well, but for more longevity, you can limit direct heat exposure to the panels.

Regular Cleaning: You can clean the panels with mild soap or detergent for a longer aesthetic look. Avoid using strong chemical cleaners on your panels.

Avoid Scratches: Even though Denwud PVC foam boards are tough, sharp objects can still cause scratches on them. Use protective pads or matting when you place heavy objects on the boards to prevent scratches on the surface.

Regular Checkup: Examine the PVC foam boards for damage on a regularly basis. If you find any damage, such as dents, cracks, or delamination, contact the manufacturer or an expert for the proper repair or replacement.

Even though the quality of PVC boards in Kerala might differ based on manufacturers, size, and suppliers, it is best to choose PVC foam board manufacturers in Kerala. Denwud provides high-quality products, follows industry standards, and offers installation and maintenance guidelines that are appropriate.

You should also remember to ask PVC foam sheet manufacturers in Kerala for specific advice on installation methods, maintenance schedules, and any warranties or after-sales support they might provide. By doing so, you can guarantee the correct installation and long-term performance of PVC foam boards.

Recent Blogs

How to make Kitchen attractive?

09 Oct, 2021

Interior design materials that are the most Eco-Fr...

11 Oct, 2021

Ideas for Stunning Ceilings

11 Oct, 2021

Looking for an appropriate Gate for your House?

29 Oct, 2021

Manufacturing and Resistance of WPC Boards, PVC Sh...

29 Oct, 2021

Why most people choose PVC Walls

19 Jan, 2022

How Amazingly Facade Adorns An Architecture!

02 Mar, 2022

Advantages of WPC Boards Over Plywoods

20 Dec, 2023

Creating Stunning Outdoor Spaces with Denwud's...

08 Jan, 2024

5 Reasons Why You Should Choose PVC Foam Sheets...

10 Jan, 2024

How to Create an Eco-Friendly Interior

29 Jan, 2024

5 Creative Ideas for Kitchen Cabinets

06 Feb, 2024

Benefits of Choosing WPC Boards | Denwudn | Kerala

14 Feb, 2024

Interior Design Ideas with Fluted Wall and Ceiling...

22 Feb, 2024

Why WPC Is The Architect’s New Favorite

11 Mar, 2024

Advantages of PVC Furniture: Stylish, Durable, and...

19 Mar, 2024

4 Reasons Why PVC Windows and Doors Are the Ultima...

27 Mar, 2024

Which is the Superior Choice? WPC Doors vs. FRP Do...

11 Apr, 2024

5 Reasons why you should use WPC doors

14 May, 2024

Choose Sustainability with WPC Board: The Future o...

30 May, 2024

Comparing WPC Boards to Traditional Wood: Pros and...

25 Jun, 2024

Choosing the Right PVC Foam Board for Your Project...

25 Jul, 2024

Transforming Interiors with PVC Foam Board: Modern...

16 Aug, 2024

Maintaining and caring for WPC boards: Tips for Lo...

28 Aug, 2024

Why WPC Boards Are the Perfect Eco-Friendly Altern...

11 Oct, 2024

Building Your Dream Interior? Here’s Why WPC and P...

29 Oct, 2024

How to Select the Proper PVC Foam Board Thickness...

07 Nov, 2024

Top Reasons to Choose Multiwood Sheets for Your Ho...

15 Nov, 2024

How to Choose the Best Multiwood Dealer for Your H...

05 Dec, 2024

Cost-Effective Solutions: How PVC Foam Boards Can...

28 Dec, 2024

The Process of Manufacturing WPC Boards: From Wast...

09 Jan, 2025

How Denwud Sheets Offer a Budget-Friendly Solution...

30 Jan, 2025

Why Choose WPC Boards for Your Home Renovation in...

14 Feb, 2025

WPC Boards for Outdoor Use: Durability and Weather...

25 Feb, 2025

Comparison of WPC Boards with Other Composite Mate...

06 Mar, 2025

Why Multiwood is the Preferred Choice for Modern H...

14 Mar, 2025

How to Choose the Best Multiwood Dealers for Your...

11 Apr, 2025

Advantages of Using Multiwood Sheets Over Plywood

25 Apr, 2025

Where to Find the Best Multiwood Sheets for Your H...

05 May, 2025

How Multiwood Dealers Are Meeting the Needs of Mod...

16 May, 2025

Local Sourcing vs Online Purchase: Where to Buy PV...

05 Jun, 2025

How to Use WPC Boards for Wardrobes and Interior F...

19 Jun, 2025

The Beginner’s Guide to Using Multiwood Sheets in...

07 Jul, 2025

Top Mistakes to Avoid When Using PVC Foam Boards i...

16 Jul, 2025

Everything You Should Know About Waterproof WPC Bo...

07 Aug, 2025

WPC Board vs PVC Board: Which One Should You Choo...

28 Aug, 2025

Emerging Trends in Multiwood Products and How Deal...

12 Sep, 2025

Creative Ideas for Kids’ Room Decor Using PVC Foam...

25 Sep, 2025

PVC Foam Board vs. Plywood: The Ultimate Compariso...

08 Oct, 2025

Top Reasons to Choose WPC Bathroom Doors for India...

30 Oct, 2025

A Guide to Choosing the Right Multiwood Dealer for...

27 Nov, 2025

The Long-Term Financial Benefits of Choosing WPC B...

01 Dec, 2025

The Ultimate Guide to 3-Layer WPC Boards and Their...

23 Dec, 2025

Why You Should Choose Denwud’s 3-Layered WPC Board...

29 Dec, 2025

How to Choose the Right Decorative Laminate Sheet

22 Jan, 2026