How to Select the Proper PVC Foam Board Thickness for Your Project

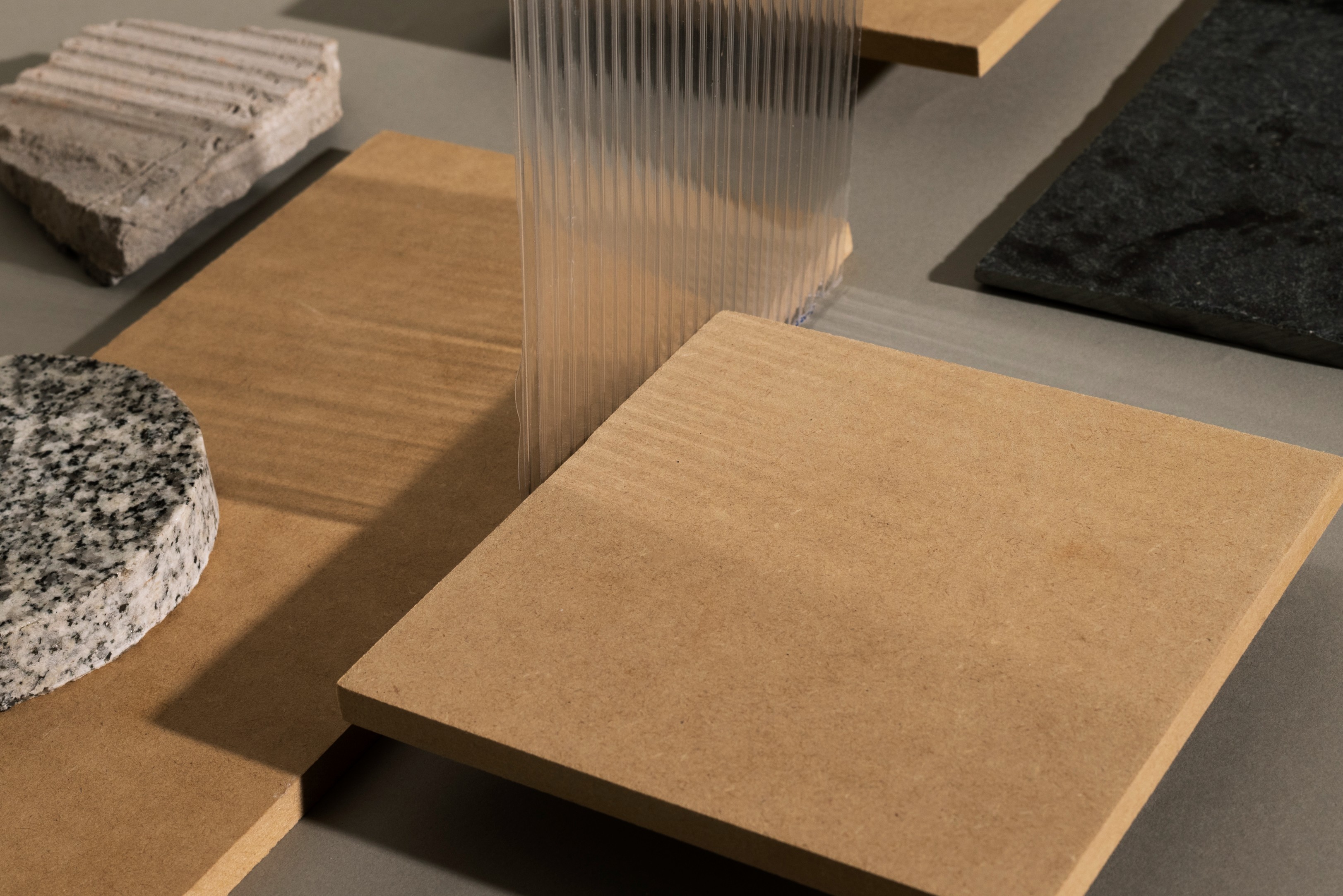

Projects requiring a material that is lightweight, flexible, strong, and easy to cut are ideal for PVC foam boards. For instance, Denwud PVC Boards are flexible, high-impact resistant, and have an excellent surface finish for interior design and outdoor billboard advertising.

However, much effort and care should be taken when selecting the perfect thickness of the PVC board for the best outcome. This guide will teach you how to properly consider the thickness of your board and explain why PVC boards have grown to be so popular with consumers.

What is PVC Foam Board?

PVC foam boards, also known as polyvinyl chloride foam sheets, are smooth, stiff plastic sheets. Due to these properties, they are widely applied to construction works, interior design materials, and even serial advertising because of their ability to combine reinforced strength with flexibility. It also comes in different thicknesses as PVC foams and boards; this is also waterproof, chemical resistant, and fire retardant.

This company deals with PVC foam sheets with a variety that is excellent for both indoor and outdoor applications. Termite-resistant boards are highly resistant to rust and possess good insulation; such boards can be used in several applications.

Why Thickness Matters

One of the most important specifications of a PVC board is its thickness grade, which would define its uses in a specific application. The boards of increased thickness provide higher rigidity and increased tensile strength for applications that require loads, whereas boards of smaller thicknesses have greater elasticity and ease in handling and are suitable for small and finishing works. Selecting the right thickness makes it possible to produce a project that is strong enough to withstand several uses and, at the same time, should not be very expensive to make.

Common PVC Board Thicknesses and Their Uses

Let’s look at common PVC board thicknesses and how they’re used:

8mm Thickness

This thickness level is suitable for denser applications such as kitchen cabinets, furniture, and exterior signage. Boards with thicknesses varying from 6mm to 8mm are particularly stable and suitable for mild force or even weight; a good board for quite large applications.

10-12mm Thickness

For structural use of the material, such as in the carving of cabinets, shelves, and directional signs, the thickness is between 10 and 12 mm. This thickness is ideal for projects requiring high strength and surface rigidity with added extra insulation favouring added thickness. It is efficient when used in constructions that require long-lasting furniture or if the PVC boards are to be constructed outside.

15mm and Above

Thicker PVC boards (15 mm and above) are used for heavy-duty applications where maximum stability is required. This thickness is suitable for outdoor billboards, ceiling panelling, and custom furniture. While it can be more costly, the 15mm board is incredibly durable and capable of handling high-impact or heavy loads.

Factors to Consider When Choosing PVC Foam Board Thickness

To choose the right thickness for your project, consider these factors:

1. Project Type and Purpose

Consider the kind of work you are doing before thinking about the thickness. For example, when using foam PVC for decoration purposes like a short-term sign or an appealing item put across the room, a slim sheet will work well. Larger projects require more substantial boards to use, as they will be strong for frequent use and durable for long use.

2. Indoor vs. Outdoor Use

The environment where the board will be used also matters. If the board will be exposed to outdoor elements, opt for a thicker sheet to prevent warping or bending. PVC sheets are generally water and heat-resistant, but thicker sheets like Denwud’s outdoor-rated boards will last longer when exposed to harsh weather conditions.

3. Desired Flexibility

Thinner PVC sheets are easier to bend, cut, and shape. They’re perfect for intricate designs or creative projects that require some flexibility. Thicker sheets are more rigid, so if flexibility isn’t necessary, a thicker board may be the best option.

4. Budget Considerations

Thicker PVC boards cost more than thin ones; this is despite the fact that they may both have similar uses. When considering the type of board you wish to buy, it should be remembered that, if extra force is not applied, a thin board is enough. More massive boards are typically more rigid; however, less thick boards can provide adequate stiffness for a great deal of interior applications.

5. Weight Load Requirements

For projects with additional weight-bearing application purposes like furniture, shelving, or structural panelling, then the thicker PVC board would be most suitable. Thicker boards are more appropriate to support something and do not twist or snap along the way.

Choosing the Right Supplier

You might have searched for PVC foam sheet near me when looking for good-quality PVC sheets. Here Denwud presents a selection of our PVC boards in various thicknesses to suit any task. It is a company that specialises in producing PVC boards that are characterised by high durability, environmental friendliness, and a sleek appearance on the surface. Denwud’s product offers the best solution, whether it is a home improvement endeavour or the work of a professional.

Conclusion

Selecting the right thickness of PVC board is essential to ensure the success and longevity of your project. Consider your project’s purpose, location, flexibility needs, and budget to find the most suitable thickness. Whether you’re building furniture, setting up signage, or working on an interior design project, Denwud PVC foam sheets offer the right blend of quality, durability, and cost-effectiveness.

Next time you’re planning a project, make sure to pick the right thickness to achieve the best results. PVC boards are a versatile, durable, and affordable option that brings creativity and functionality to any project.

Recent Blogs

How to make Kitchen attractive?

09 Oct, 2021

Interior design materials that are the most Eco-Fr...

11 Oct, 2021

Ideas for Stunning Ceilings

11 Oct, 2021

Looking for an appropriate Gate for your House?

29 Oct, 2021

Manufacturing and Resistance of WPC Boards, PVC Sh...

29 Oct, 2021

Why most people choose PVC Walls

19 Jan, 2022

How Amazingly Facade Adorns An Architecture!

02 Mar, 2022

Advantages of WPC Boards Over Plywoods

20 Dec, 2023

Creating Stunning Outdoor Spaces with Denwud's...

08 Jan, 2024

5 Reasons Why You Should Choose PVC Foam Sheets...

10 Jan, 2024

Installing and Maintaining PVC and WPC Products

18 Jan, 2024

How to Create an Eco-Friendly Interior

29 Jan, 2024

5 Creative Ideas for Kitchen Cabinets

06 Feb, 2024

Benefits of Choosing WPC Boards | Denwudn | Kerala

14 Feb, 2024

Interior Design Ideas with Fluted Wall and Ceiling...

22 Feb, 2024

Why WPC Is The Architect’s New Favorite

11 Mar, 2024

Advantages of PVC Furniture: Stylish, Durable, and...

19 Mar, 2024

4 Reasons Why PVC Windows and Doors Are the Ultima...

27 Mar, 2024

Which is the Superior Choice? WPC Doors vs. FRP Do...

11 Apr, 2024

5 Reasons why you should use WPC doors

14 May, 2024

Choose Sustainability with WPC Board: The Future o...

30 May, 2024

Comparing WPC Boards to Traditional Wood: Pros and...

25 Jun, 2024

Choosing the Right PVC Foam Board for Your Project...

25 Jul, 2024

Transforming Interiors with PVC Foam Board: Modern...

16 Aug, 2024

Maintaining and caring for WPC boards: Tips for Lo...

28 Aug, 2024

Why WPC Boards Are the Perfect Eco-Friendly Altern...

11 Oct, 2024

Building Your Dream Interior? Here’s Why WPC and P...

29 Oct, 2024

Top Reasons to Choose Multiwood Sheets for Your Ho...

15 Nov, 2024

How to Choose the Best Multiwood Dealer for Your H...

05 Dec, 2024

Cost-Effective Solutions: How PVC Foam Boards Can...

28 Dec, 2024

The Process of Manufacturing WPC Boards: From Wast...

09 Jan, 2025

How Denwud Sheets Offer a Budget-Friendly Solution...

30 Jan, 2025

Why Choose WPC Boards for Your Home Renovation in...

14 Feb, 2025

WPC Boards for Outdoor Use: Durability and Weather...

25 Feb, 2025

Comparison of WPC Boards with Other Composite Mate...

06 Mar, 2025

Why Multiwood is the Preferred Choice for Modern H...

14 Mar, 2025

How to Choose the Best Multiwood Dealers for Your...

11 Apr, 2025

Advantages of Using Multiwood Sheets Over Plywood

25 Apr, 2025

Where to Find the Best Multiwood Sheets for Your H...

05 May, 2025

How Multiwood Dealers Are Meeting the Needs of Mod...

16 May, 2025

Local Sourcing vs Online Purchase: Where to Buy PV...

05 Jun, 2025

How to Use WPC Boards for Wardrobes and Interior F...

19 Jun, 2025

The Beginner’s Guide to Using Multiwood Sheets in...

07 Jul, 2025

Top Mistakes to Avoid When Using PVC Foam Boards i...

16 Jul, 2025

Everything You Should Know About Waterproof WPC Bo...

07 Aug, 2025

WPC Board vs PVC Board: Which One Should You Choo...

28 Aug, 2025

Emerging Trends in Multiwood Products and How Deal...

12 Sep, 2025

Creative Ideas for Kids’ Room Decor Using PVC Foam...

25 Sep, 2025

PVC Foam Board vs. Plywood: The Ultimate Compariso...

08 Oct, 2025

Top Reasons to Choose WPC Bathroom Doors for India...

30 Oct, 2025

A Guide to Choosing the Right Multiwood Dealer for...

27 Nov, 2025

The Long-Term Financial Benefits of Choosing WPC B...

01 Dec, 2025

The Ultimate Guide to 3-Layer WPC Boards and Their...

23 Dec, 2025

Why You Should Choose Denwud’s 3-Layered WPC Board...

29 Dec, 2025

How to Choose the Right Decorative Laminate Sheet

22 Jan, 2026