The Process of Manufacturing WPC Boards: From Waste to Wonder

The Process of Manufacturing WPC Boards: From Waste to Wonder

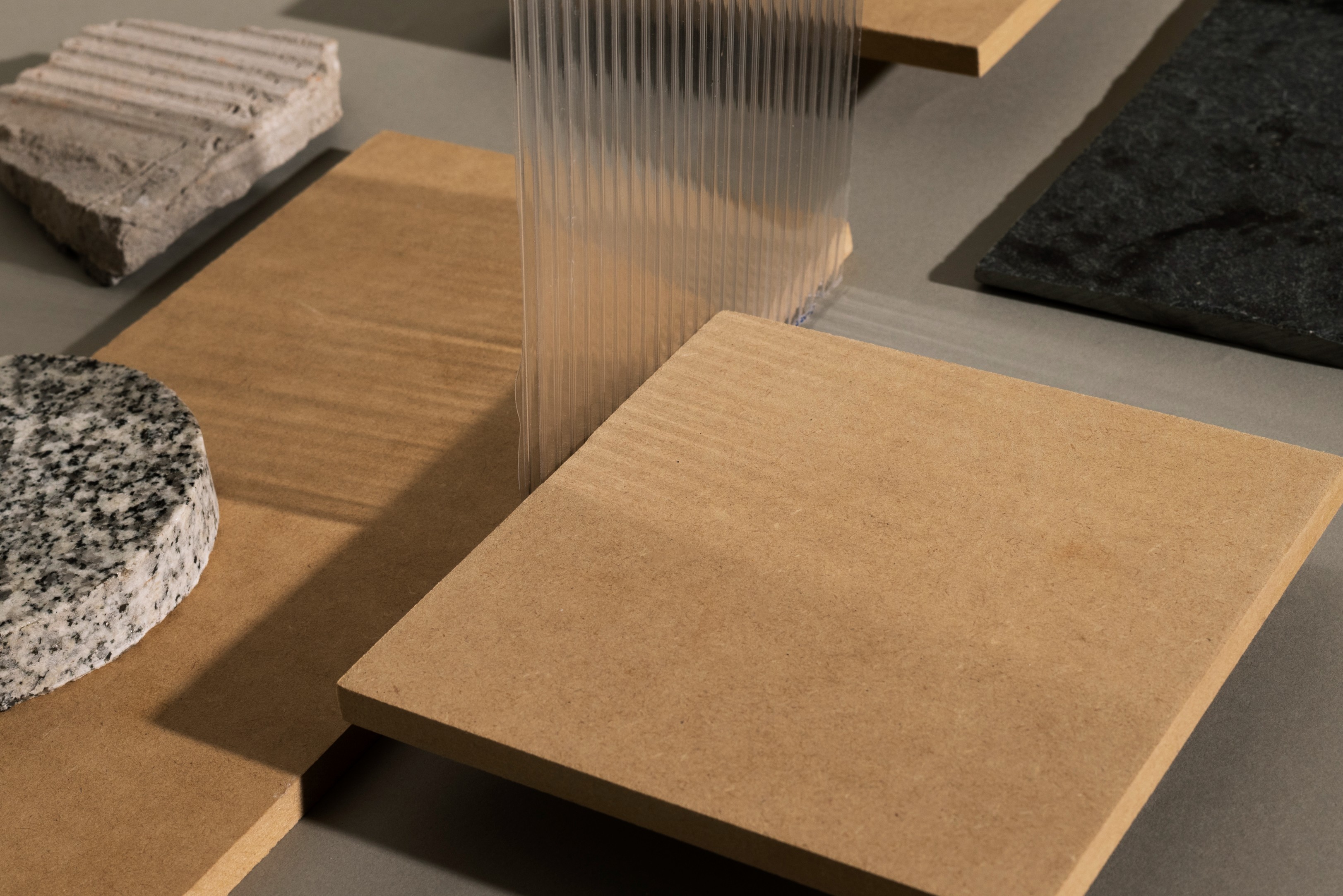

WPC boards, or Wood-Plastic Composite boards, are a green and strong choice instead of regular wood products. They are especially popular in places like Kerala that care about the environment. They are changing the way buildings and construction are done. What makes these boards special is how they are made, using waste to create useful material for things like decking, fencing, and cladding. Here is a simple guide on how these boards are made.

Material Selection and Preparation

Raw materials with which the journey of the boards begins include:

Wood Waste: Any by-products obtained from sawdust, wood chips, or wood flour from a sawmill or a woodworking industry.

Plastics: Recycled plastics are generally polyethylene, polypropylene, or PVC materials from post-consumer or industrial waste streams.

This combination also decreases landfill waste but preserves precious natural resources. For improving the strength, appearance, and resistance against the outer world, additives include stabilizers, UV inhibitors, and colorants.

Compounding: The Art of Blending

Wood particles, with plastics added to it, undergo compounding. Strictly controlled conditions allow the wood and plastic particles to blend into each other perfectly. This step of compounding will give the homogeneous mixture required for boards of very high quality.

Compounding also allows manufacturers to perfect the composition, balancing the natural feel of wood with the durability of plastic. The outcomes? A material that resists rot, pests, and moisture while maintaining the look.

Extrusion: Shaping the WPC Boards

After that, the mixture is pushed through an extruder. In order to create the required profiles for the boards, the mixture is heated and forced through a mould.

The process allows for continuous extrusion, meaning it is also efficient for massive production.

It also gives flexibility in designing boards of different sizes, textures, and finishes to suit different applications.

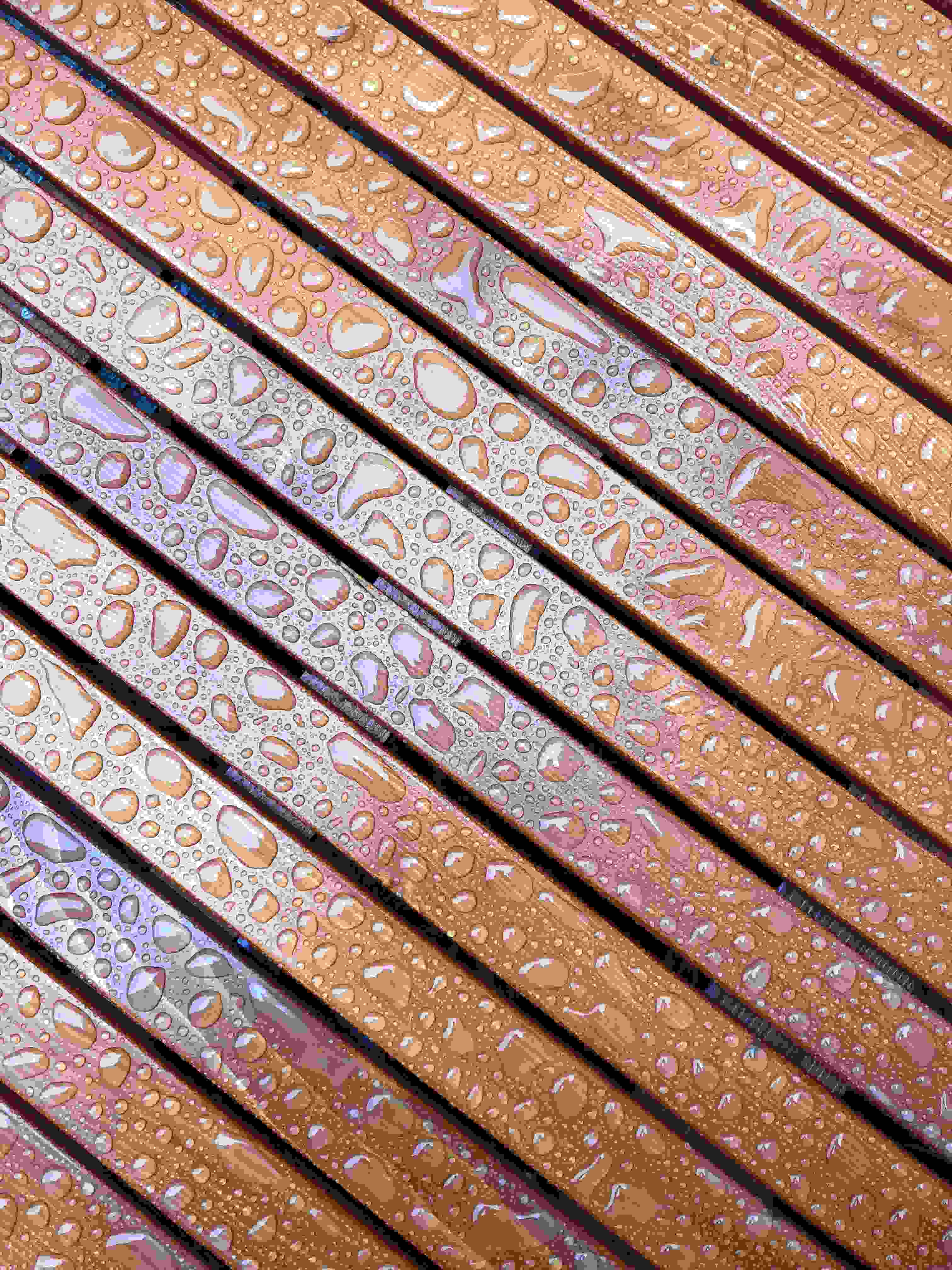

In regions like Kerala, where the humidity may influence the traditional wood, but these boards are not affected by moisture, an essential feature for long-lasting performance.

Cooling and Solidifying

The newly formed boards are cooled after extrusion to harden the structure. This will prevent warping and maintain the dimensionality. Proper cooling helps with the board strength and durability. Hence appropriate for high-stress applications.

Cutting, Finishing, and Quality Control

Once set, the boards are cut to desired lengths and are subjected to various finishing processes:

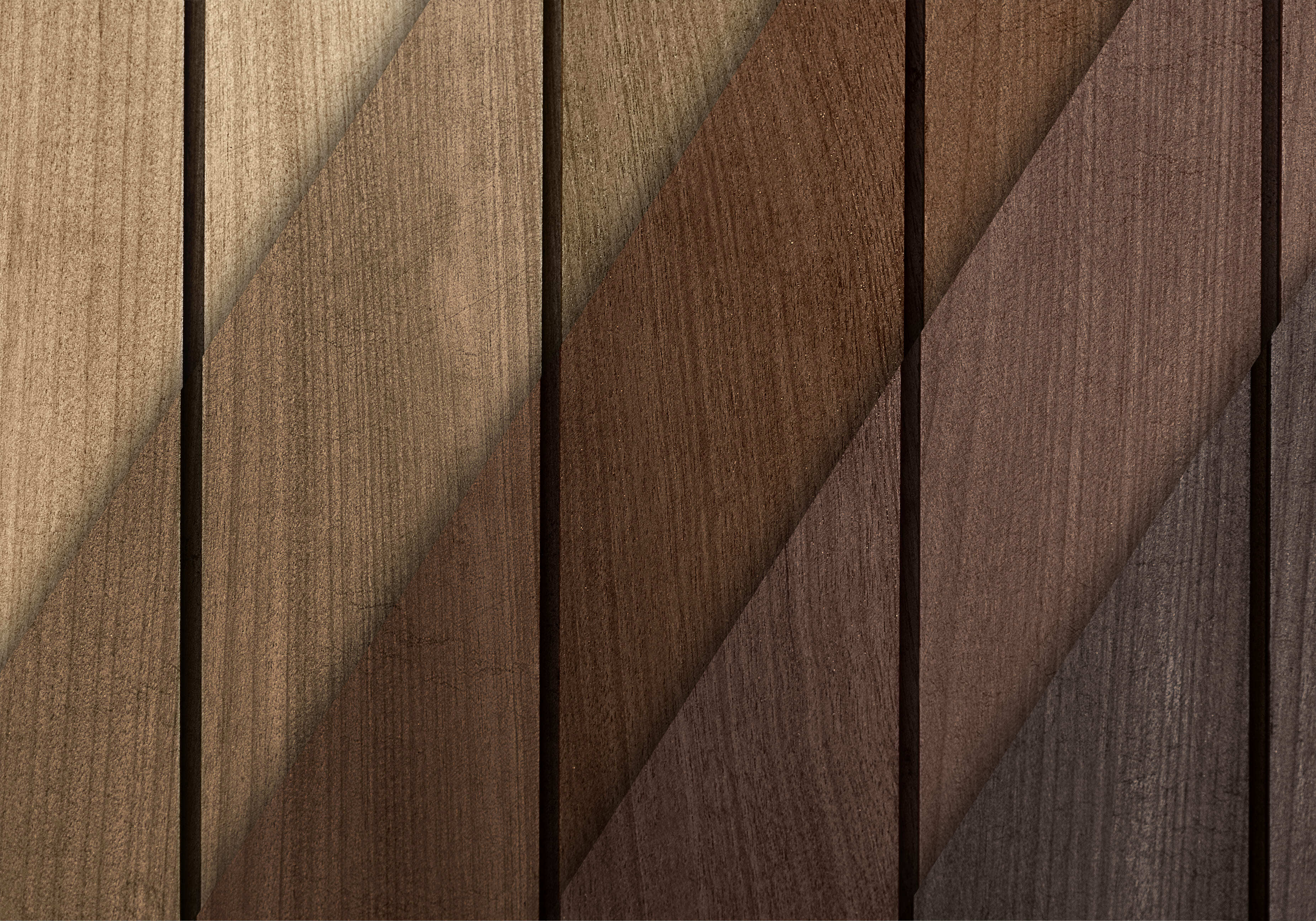

Sanding: It smooths the surface to make it look good. Embossing: Adding textures that imitate natural wood grain. Coating: Applied for protection and visual effect.

The boards also undergo tests for mechanical strength, moisture resistance, and the surface finish so that each component meets the relevant industry standards or customer expectations.

WPC Boards in Kerala: A Sustainable Choice

WPC boards are extensively used in Kerala as they are an eco-friendly building material and can withstand the humid climate of the region. They are eco-friendly and multi-functional for indoor and outdoor use through recycling and innovation.

Conclusion

From waste to wonder, the manufacturing process of the boards exemplifies how innovation can drive sustainability. With wood waste and recycled plastics combined, these boards reduce environmental impact while delivering unmatched durability and aesthetics. Both in Kerala and beyond, these boards are leading the way for a greener, more sustainable future in construction and design.

And Denwud has become the tag bearer for a sustainable country with our productions. Choose your materials from Denwud to choose them wisely.

Recent Blogs

How to make Kitchen attractive?

09 Oct, 2021

Interior design materials that are the most Eco-Fr...

11 Oct, 2021

Ideas for Stunning Ceilings

11 Oct, 2021

Looking for an appropriate Gate for your House?

29 Oct, 2021

Manufacturing and Resistance of WPC Boards, PVC Sh...

29 Oct, 2021

Why most people choose PVC Walls

19 Jan, 2022

How Amazingly Facade Adorns An Architecture!

02 Mar, 2022

Advantages of WPC Boards Over Plywoods

20 Dec, 2023

Creating Stunning Outdoor Spaces with Denwud's...

08 Jan, 2024

5 Reasons Why You Should Choose PVC Foam Sheets...

10 Jan, 2024

Installing and Maintaining PVC and WPC Products

18 Jan, 2024

How to Create an Eco-Friendly Interior

29 Jan, 2024

5 Creative Ideas for Kitchen Cabinets

06 Feb, 2024

Benefits of Choosing WPC Boards | Denwudn | Kerala

14 Feb, 2024

Interior Design Ideas with Fluted Wall and Ceiling...

22 Feb, 2024

Why WPC Is The Architect’s New Favorite

11 Mar, 2024

Advantages of PVC Furniture: Stylish, Durable, and...

19 Mar, 2024

4 Reasons Why PVC Windows and Doors Are the Ultima...

27 Mar, 2024

Which is the Superior Choice? WPC Doors vs. FRP Do...

11 Apr, 2024

5 Reasons why you should use WPC doors

14 May, 2024

Choose Sustainability with WPC Board: The Future o...

30 May, 2024

Comparing WPC Boards to Traditional Wood: Pros and...

25 Jun, 2024

Choosing the Right PVC Foam Board for Your Project...

25 Jul, 2024

Transforming Interiors with PVC Foam Board: Modern...

16 Aug, 2024

Maintaining and caring for WPC boards: Tips for Lo...

28 Aug, 2024

Why WPC Boards Are the Perfect Eco-Friendly Altern...

11 Oct, 2024

Building Your Dream Interior? Here’s Why WPC and P...

29 Oct, 2024

How to Select the Proper PVC Foam Board Thickness...

07 Nov, 2024

Top Reasons to Choose Multiwood Sheets for Your Ho...

15 Nov, 2024

How to Choose the Best Multiwood Dealer for Your H...

05 Dec, 2024

Cost-Effective Solutions: How PVC Foam Boards Can...

28 Dec, 2024

How Denwud Sheets Offer a Budget-Friendly Solution...

30 Jan, 2025

Why Choose WPC Boards for Your Home Renovation in...

14 Feb, 2025

WPC Boards for Outdoor Use: Durability and Weather...

25 Feb, 2025

Comparison of WPC Boards with Other Composite Mate...

06 Mar, 2025

Why Multiwood is the Preferred Choice for Modern H...

14 Mar, 2025

How to Choose the Best Multiwood Dealers for Your...

11 Apr, 2025

Advantages of Using Multiwood Sheets Over Plywood

25 Apr, 2025

Where to Find the Best Multiwood Sheets for Your H...

05 May, 2025

How Multiwood Dealers Are Meeting the Needs of Mod...

16 May, 2025

Local Sourcing vs Online Purchase: Where to Buy PV...

05 Jun, 2025

How to Use WPC Boards for Wardrobes and Interior F...

19 Jun, 2025

The Beginner’s Guide to Using Multiwood Sheets in...

07 Jul, 2025

Top Mistakes to Avoid When Using PVC Foam Boards i...

16 Jul, 2025

Everything You Should Know About Waterproof WPC Bo...

07 Aug, 2025

WPC Board vs PVC Board: Which One Should You Choo...

28 Aug, 2025

Emerging Trends in Multiwood Products and How Deal...

12 Sep, 2025

Creative Ideas for Kids’ Room Decor Using PVC Foam...

25 Sep, 2025

PVC Foam Board vs. Plywood: The Ultimate Compariso...

08 Oct, 2025

Top Reasons to Choose WPC Bathroom Doors for India...

30 Oct, 2025

A Guide to Choosing the Right Multiwood Dealer for...

27 Nov, 2025

The Long-Term Financial Benefits of Choosing WPC B...

01 Dec, 2025

The Ultimate Guide to 3-Layer WPC Boards and Their...

23 Dec, 2025

Why You Should Choose Denwud’s 3-Layered WPC Board...

29 Dec, 2025

How to Choose the Right Decorative Laminate Sheet

22 Jan, 2026

What Are 5-Layer WPC Boards? Features, Benefits, a...

02 Feb, 2026

What Makes a 5-Layer WPC Board Different from a Re...

20 Feb, 2026