What Are 5-Layer WPC Boards? Features, Benefits, and Applications

Introduction to 5-Layer WPC Boards

Anyone who has worked with interiors for a while knows this truth: not all boards age well. What looks strong on day one can start sagging, swelling, or breaking down within a few years—especially in humid regions. That’s exactly why engineered materials have slowly replaced traditional wood-based boards in many projects. Denwud was among the early companies to introduce 5-layer WPC boards in Kerala, helping shift interior material choices toward stronger, more stable alternatives built for real conditions.

Instead of relying only on surface appearance, these boards are designed from the inside out.

What Are 5-Layer WPC Boards?

5-layer WPC boards are not just thicker boards; they are smarter boards. Unlike standard composite boards made from a single mixed core, these boards are built in layers. Each layer has a purpose, whether it’s strength, balance, or surface finish.

This layered design makes the board more predictable in performance. It doesn’t bend unexpectedly, crack at pressure points, or behave differently from one end to the other. Compared to regular WPC boards, the 5-layer version offers better control during fabrication and far fewer surprises after installation.

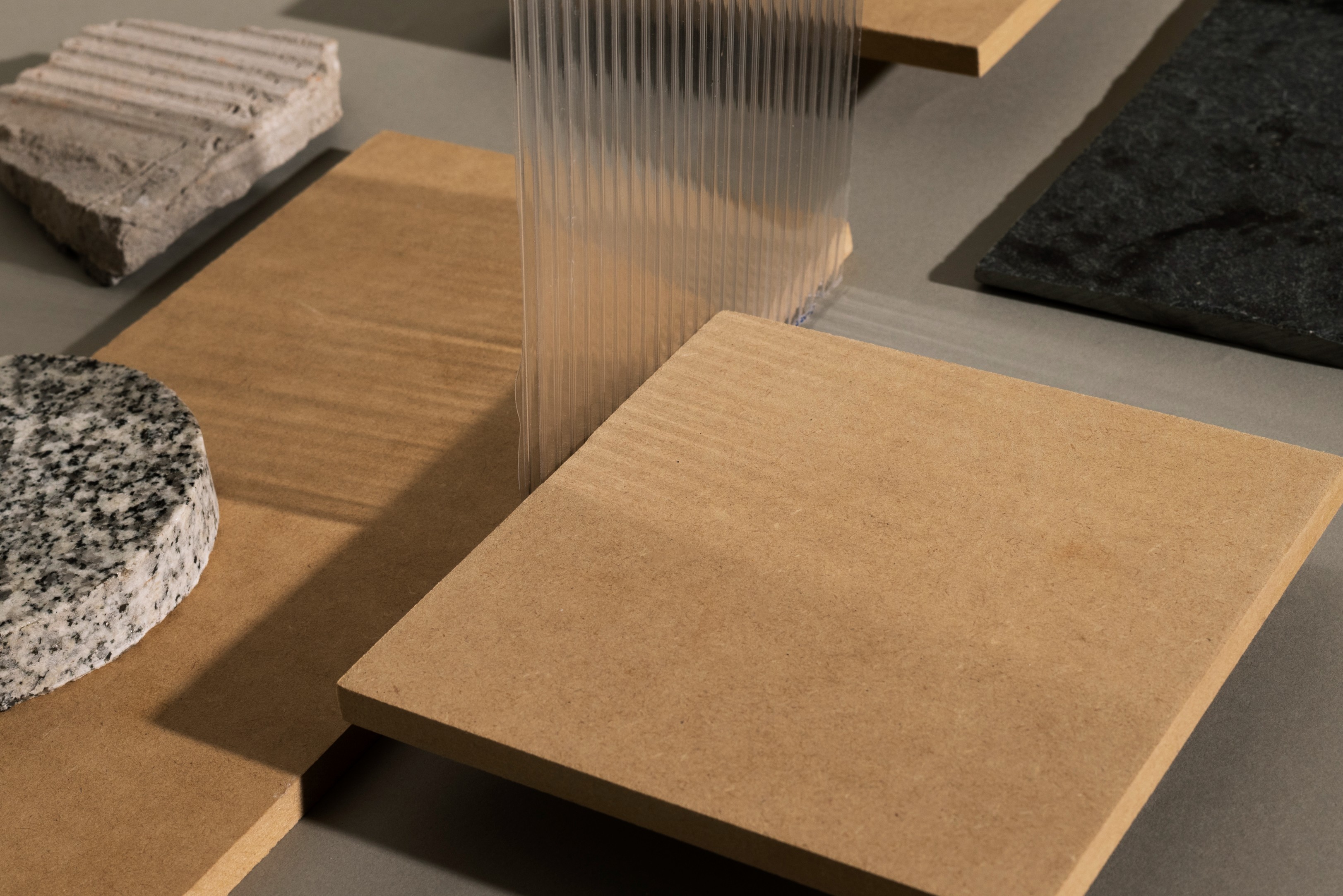

Composition and Structure of 5-Layer WPC Boards

The internal build is what gives these boards their edge. The outer layers are dense and smooth, which helps with finishing and lamination. Beneath those are reinforced layers that improve load-bearing strength and impact resistance. The central layer holds everything together, keeping the board balanced and stable.

Because the density is evenly distributed, carpenters notice fewer issues while cutting or drilling. Screws sit firmly, edges don’t crumble, and joints remain intact. This consistency is one of the biggest reasons professionals prefer layered boards over conventional options.

Key Features and Benefits

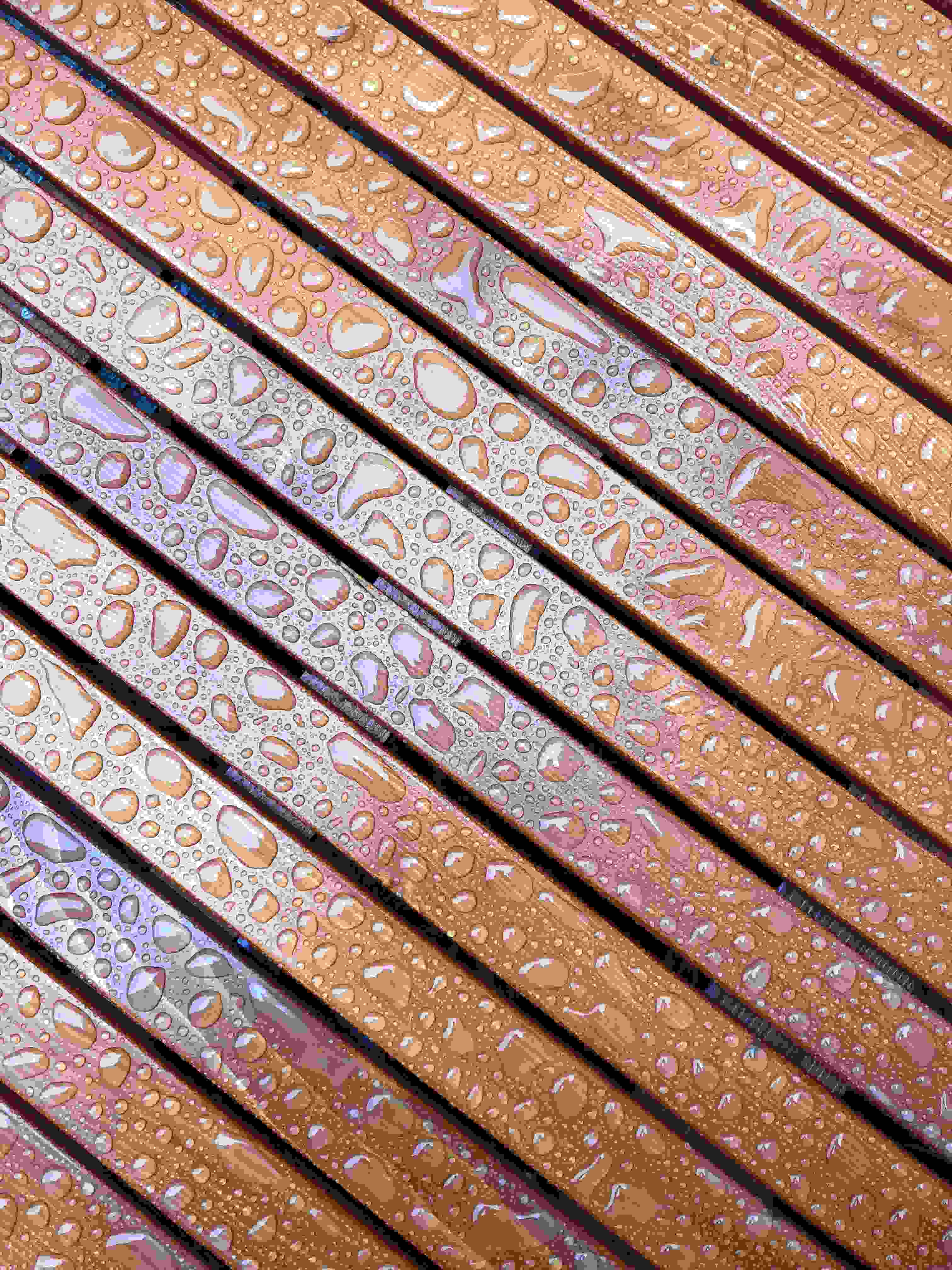

One feature that stands out immediately is moisture resistance. These boards do not absorb water the way plywood or MDF does. That alone prevents many long-term problems like swelling, peeling, and deformation.

They are also termite-proof, which removes the need for chemical treatments. Another practical feature is surface uniformity. There are no soft patches or weak zones, which means the board performs the same way across its entire surface.

The real benefit shows over time. These boards are built to stay stable year after year. They don’t demand constant care, repairs, or replacement. Once installed properly, they simply do their job.

In regions with high humidity, wpc boards in Kerala have become a reliable option because they handle climate stress better than traditional materials. This reliability reduces long-term expenses and saves time that would otherwise be spent on maintenance or rework.

Applications of 5-Layer WPC Boards

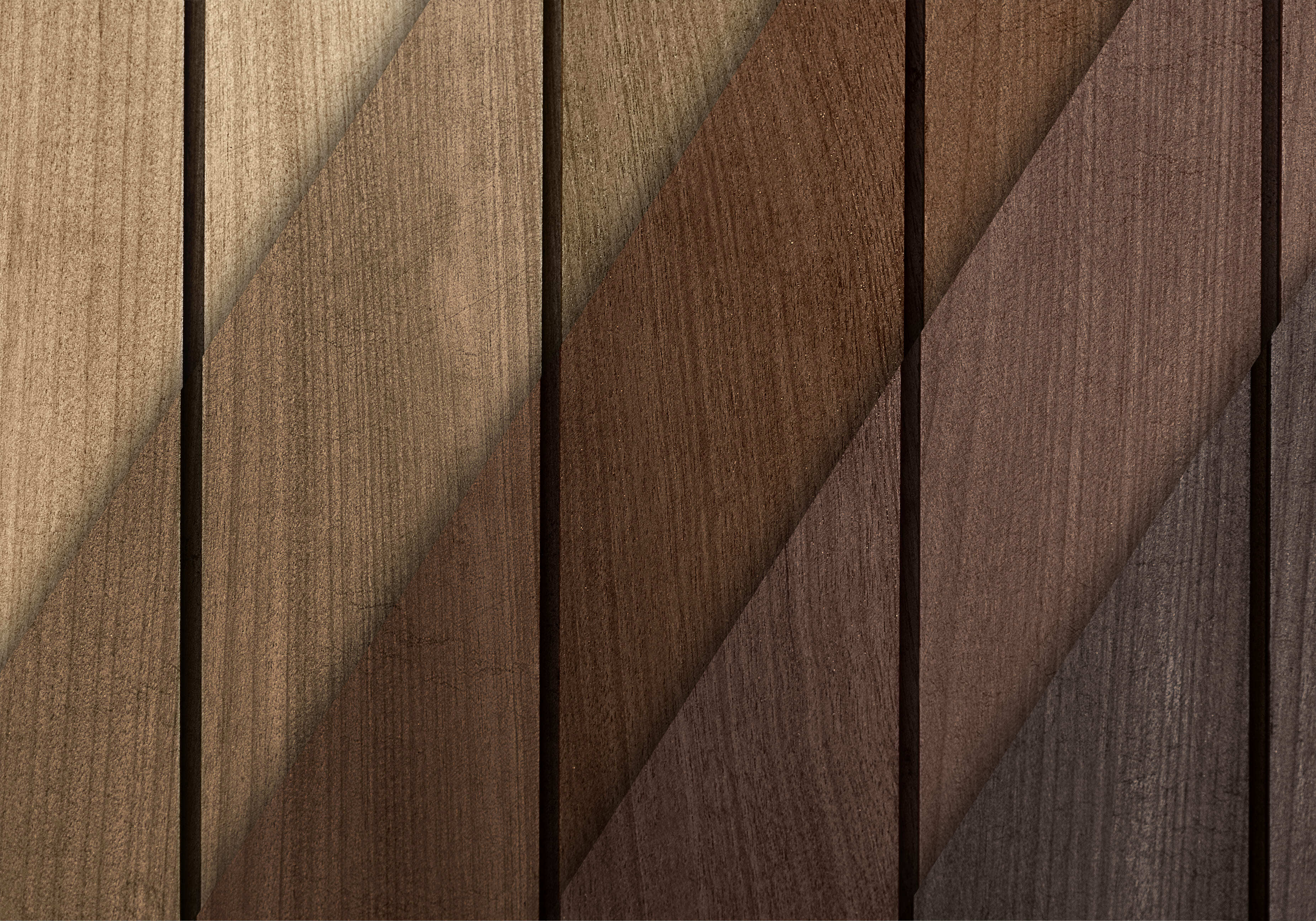

Due to their strength and resistance to moisture, 5-layer WPC boards have found a lot of applications in kitchens, wardrobes, bathroom cabinets, partitions, and wall paneling. They are also popular in office interiors and commercial locations where cost savings in the short term are not as important as longevity.

Designers like a clean finish, and installers love the ease with which the boards can be handled. The outcome is a material that can be applicable in various interior design types and purposes.

5-Layer WPC Boards vs Traditional Materials

Traditional boards have limitations that many people only notice after installation. Plywood can swell. MDF weakens with moisture. Particle boards lose strength quickly under load.

5-layer WPC boards are engineered to avoid these issues. Their layered structure distributes stress more evenly and helps the board retain its shape. This makes them more dependable over time, especially in demanding environments.

Installation and Maintenance Overview

Installation is straightforward. These boards work well with standard tools and fittings. Screws hold firmly without splitting the board, and edges remain clean after cutting.

Maintenance is simple. There’s no need for polishing, sealing, or chemical treatments. Regular cleaning is enough to keep the surface in good condition, even in high-use areas.

Environmental and Sustainability Benefits

From a sustainability point of view, 5-layer WPC boards reduce dependence on natural timber. They are recyclable and designed to last longer, which means fewer replacements and less material waste.

They also avoid the use of harmful preservatives, making indoor spaces safer. This balance between performance and responsibility makes them suitable for modern interior projects.

Conclusion

Interior materials are expected to do more today—handle moisture, carry weight, stay stable, and still look good over time. 5-layer WPC boards meet these expectations without constant upkeep. By introducing layered WPC board solutions early on, Denwud has helped push interior practices in Kerala toward materials that are more durable, practical, and future-ready.

Recent Blogs

How to make Kitchen attractive?

09 Oct, 2021

Interior design materials that are the most Eco-Fr...

11 Oct, 2021

Ideas for Stunning Ceilings

11 Oct, 2021

Looking for an appropriate Gate for your House?

29 Oct, 2021

Manufacturing and Resistance of WPC Boards, PVC Sh...

29 Oct, 2021

Why most people choose PVC Walls

19 Jan, 2022

How Amazingly Facade Adorns An Architecture!

02 Mar, 2022

Advantages of WPC Boards Over Plywoods

20 Dec, 2023

Creating Stunning Outdoor Spaces with Denwud's...

08 Jan, 2024

5 Reasons Why You Should Choose PVC Foam Sheets...

10 Jan, 2024

Installing and Maintaining PVC and WPC Products

18 Jan, 2024

How to Create an Eco-Friendly Interior

29 Jan, 2024

5 Creative Ideas for Kitchen Cabinets

06 Feb, 2024

Benefits of Choosing WPC Boards | Denwudn | Kerala

14 Feb, 2024

Interior Design Ideas with Fluted Wall and Ceiling...

22 Feb, 2024

Why WPC Is The Architect’s New Favorite

11 Mar, 2024

Advantages of PVC Furniture: Stylish, Durable, and...

19 Mar, 2024

4 Reasons Why PVC Windows and Doors Are the Ultima...

27 Mar, 2024

Which is the Superior Choice? WPC Doors vs. FRP Do...

11 Apr, 2024

5 Reasons why you should use WPC doors

14 May, 2024

Choose Sustainability with WPC Board: The Future o...

30 May, 2024

Comparing WPC Boards to Traditional Wood: Pros and...

25 Jun, 2024

Choosing the Right PVC Foam Board for Your Project...

25 Jul, 2024

Transforming Interiors with PVC Foam Board: Modern...

16 Aug, 2024

Maintaining and caring for WPC boards: Tips for Lo...

28 Aug, 2024

Why WPC Boards Are the Perfect Eco-Friendly Altern...

11 Oct, 2024

Building Your Dream Interior? Here’s Why WPC and P...

29 Oct, 2024

How to Select the Proper PVC Foam Board Thickness...

07 Nov, 2024

Top Reasons to Choose Multiwood Sheets for Your Ho...

15 Nov, 2024

How to Choose the Best Multiwood Dealer for Your H...

05 Dec, 2024

Cost-Effective Solutions: How PVC Foam Boards Can...

28 Dec, 2024

The Process of Manufacturing WPC Boards: From Wast...

09 Jan, 2025

How Denwud Sheets Offer a Budget-Friendly Solution...

30 Jan, 2025

Why Choose WPC Boards for Your Home Renovation in...

14 Feb, 2025

WPC Boards for Outdoor Use: Durability and Weather...

25 Feb, 2025

Comparison of WPC Boards with Other Composite Mate...

06 Mar, 2025

Why Multiwood is the Preferred Choice for Modern H...

14 Mar, 2025

How to Choose the Best Multiwood Dealers for Your...

11 Apr, 2025

Advantages of Using Multiwood Sheets Over Plywood

25 Apr, 2025

Where to Find the Best Multiwood Sheets for Your H...

05 May, 2025

How Multiwood Dealers Are Meeting the Needs of Mod...

16 May, 2025

Local Sourcing vs Online Purchase: Where to Buy PV...

05 Jun, 2025

How to Use WPC Boards for Wardrobes and Interior F...

19 Jun, 2025

The Beginner’s Guide to Using Multiwood Sheets in...

07 Jul, 2025

Top Mistakes to Avoid When Using PVC Foam Boards i...

16 Jul, 2025

Everything You Should Know About Waterproof WPC Bo...

07 Aug, 2025

WPC Board vs PVC Board: Which One Should You Choo...

28 Aug, 2025

Emerging Trends in Multiwood Products and How Deal...

12 Sep, 2025

Creative Ideas for Kids’ Room Decor Using PVC Foam...

25 Sep, 2025

PVC Foam Board vs. Plywood: The Ultimate Compariso...

08 Oct, 2025

Top Reasons to Choose WPC Bathroom Doors for India...

30 Oct, 2025

A Guide to Choosing the Right Multiwood Dealer for...

27 Nov, 2025

The Long-Term Financial Benefits of Choosing WPC B...

01 Dec, 2025

The Ultimate Guide to 3-Layer WPC Boards and Their...

23 Dec, 2025

Why You Should Choose Denwud’s 3-Layered WPC Board...

29 Dec, 2025